The Differences Between Alloys and Pure Metals

Leave a Comment

Many people argue whether pure metal or metal alloys are better for a given use. But after highlighting the differences between alloys and pure metals, you’ll see why metal alloys provide several advantages over pure metals.

Chemistry

You can trace the distinction between metals and alloys back to the elements that compose them. All the atoms in a pure metal are the same. For instance, chromium is a pure metal since it’s on the periodic table. In contrast, atoms of various elements mesh to form an alloy. Stainless steel, for instance, combines chromium, iron, and carbon.

Strength

Alloys are composites of many metals, each contributing desirable features while canceling out the negative features of others. By doing so, an alloy has superior strength compared with the original metals.

Since pure metals can weaken, alloying is beneficial to generate a harder metal complex. Unlike pure metal, which consists of identical atoms, metal alloys include various elements. Alloys of metals are often significantly stronger and harder than pure metals because of their tightly packed atoms.

Gold is a prime example of this. In its purest form, gold is a surprisingly malleable and pliable metal. But you can blend gold with zinc, copper, or silver to create beautiful, durable alloy jewelry.

Heat-Resistance

Alloys have a variety of melting points due to the combination of metals they contain and their respective melting points. When you combine metals, the melting point can increase, even if one metal melts at a relatively low temperature. This has enormous practical value for industrial applications like aircraft engines, where temperatures may reach very high levels.

Stimuli Response

Adding alloying elements to pure metals like iron is a major benefit because of how fast and powerfully they respond to external stimuli. Pure metals may rust, oxidize, or corrode over time due to environmental factors like oxygen and water. Alloys, on the other hand, are mixtures of less reactive metals that extend the life of the material they form. For example, the chromium in stainless steel makes it resistant to corrosion.

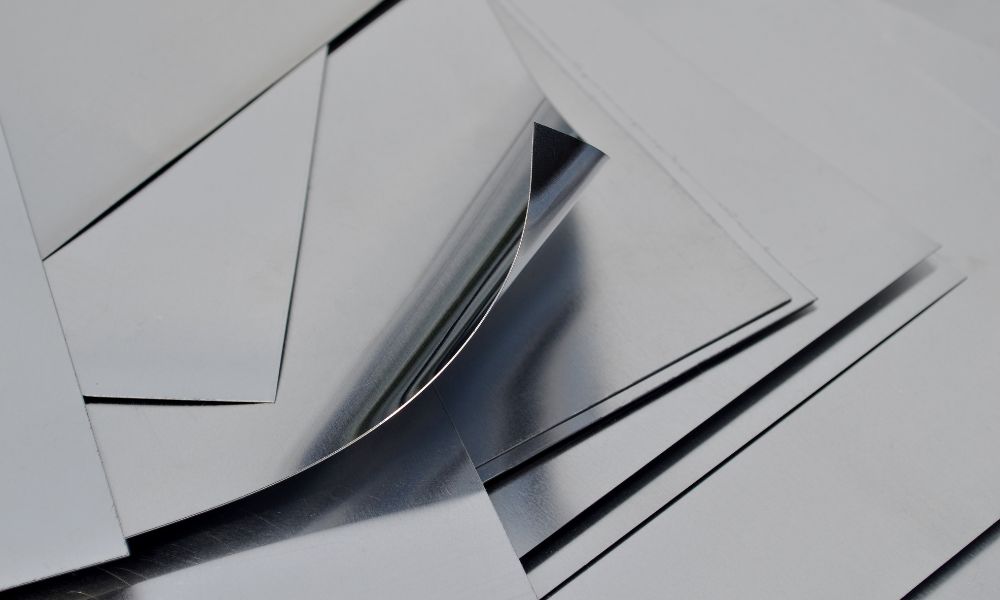

Understanding the differences between alloys and pure metals indicates why alloy is a great resource. Since 1976, Thin Metal Sales has provided customers with high-quality, thin-gauge sheet metals.

We are proud to be the best aluminum sheet metal manufacturer for any width and length. We also work with stainless steel, carbon steel, copper, and brass. You can trust the sheet metal you purchase from Thin Metal Sales is of the highest quality and has been properly cut to meet your needs.

Stainless Steel vs. Galvanized: Why Stainless Is Better

Leave a Comment

Each fabrication job is distinct, and types of steel will perform better in various contexts. It’s impossible to say whether galvanized or stainless steel is better without knowing the specifics of your fabrication job. However, it’s clear why stainless steel is better than galvanized steel when you look at the tale of the tape between the two.

What’s Galvanized Steel?

Steel with a zinc coat is galvanized steel; the coating prevents corrosion. Products made from galvanized steel may withstand prolonged weather exposure without significant damage. Galvanized steel is resistant to fresh water and salt water. Most structural steel welders will find galvanized steel easy to work with. The zinc coating on galvanized steel wears off over time, and the material eventually needs maintenance.

What’s Stainless Steel?

The addition of chromium to steel in its molten state produces stainless steel. Stainless steel is durable and won’t rust even if wet, nor does it corrode when exposed to seawater. Welders using stainless steel require unique abilities to work with greater precision on heated and cooled materials. The filler materials must be a perfect match for the welded steel.

Precipitation-hardening stainless steel is one of the few varieties of stainless steel. The composition of the metal alloy used to create steel gives rise to its many subtypes. The strength of an alloy increases with its complexity, but so does its cost.

Applications for Both Options

Stainless steel is durable and unlikely to rust in high-stress environments, like the aircraft industry. Bridges, skyscrapers, sculptures, trains, and automobiles are just some examples of structures that benefit from stainless steel’s strength and resistance to salt water. Ultimately, stainless steel is the perfect solution for large-scale, high-budget fabrication projects.

That’s not to say galvanized steel doesn’t have its place. Galvanized steel is preferable to stainless steel in chlorinated water because stainless steel corrodes faster. This metal is usually the best choice when working with a budget. It’s a common material for household plumbing and HVAC systems, fences and other security measures, and fasteners like screws and bolts. However, stainless steel is the most reliable and durable option when you don’t have to limit your spending.

Understanding that stainless steel is better than galvanized steel informs you why it’s the superior choice for most projects. Thin Metal Sales can be your stainless steel sheet manufacturer with our exceptional service that’s lasted nearly 50 years. No job is too big or small for Thin Metal Sales!