Modern Sustainability Trends in Metal Supply Chains

Comments Off on Modern Sustainability Trends in Metal Supply Chains

The global push for sustainability is reshaping industries, and the metal supply chain is no exception. As businesses and consumers alike demand greater environmental responsibility, the sector is adopting innovative practices to reduce its ecological footprint. If you’d like to learn more about these changes, we’re here to cover the top modern sustainability trends transforming how the metal supply chains operate.

Embracing the Circular Economy

A foundational shift in the metal supply chain is the move towards a circular economy. This model focuses on minimizing waste and maximizing resource utility by recycling and reusing metals. Instead of a linear “take-make-dispose” approach, the industry is developing closed-loop systems that collect end-of-life products, process them, and reintroduce them into the manufacturing cycle.

Stainless steel sales have grown significantly during this transition, driven by its durability and reusability across the industry. Regardless of the metal, though, by reducing the dependency on virgin raw material extraction, the circular economy conserves natural resources, cuts down on energy consumption, and lessens the environmental strain associated with mining.

Adopting Green Mining Practices

For the raw materials that still need extraction, green mining practices are becoming standardized. This involves adopting energy-efficient technologies and implementing strategies to minimize the environmental impact of mining operations.

Many companies are investing in renewable energy sources to power their facilities, optimizing water usage to conserve local resources, and developing advanced waste-management methods. These initiatives not only reduce the carbon footprint of extraction but also help preserve biodiversity and protect local ecosystems from long-term damage.

Enhancing Supply Chain Transparency

Stakeholders are increasingly demanding transparency throughout the supply chain to ensure metals are sourced ethically and responsibly. Businesses are using advanced technologies like blockchain to create immutable records that track materials from the mine to the final product.

This level of traceability provides verifiable proof of a metal’s origin and journey, helping to combat issues like conflict minerals and illegal mining. By ensuring ethical sourcing and full lifecycle tracking, companies can build customer trust and meet stringent regulatory requirements.

Striving for Carbon Neutrality

Achieving carbon neutrality is a major sustainability goal for the modern metal industry supply chains. Many companies are making ambitious commitments to reach net-zero emissions across their entire operations. This involves a multi-faceted approach that targets reductions in mining, processing, and transportation.

Key strategies include transitioning to electric vehicle fleets, upgrading to energy-efficient smelting processes, and investing in carbon capture technologies. These net-zero initiatives are essential for mitigating the industry’s contribution to climate change and aligning with global environmental targets.

The Role of Laser Cutting in Thin-Gauge Metal Fabrication

Comments Off on The Role of Laser Cutting in Thin-Gauge Metal Fabrication

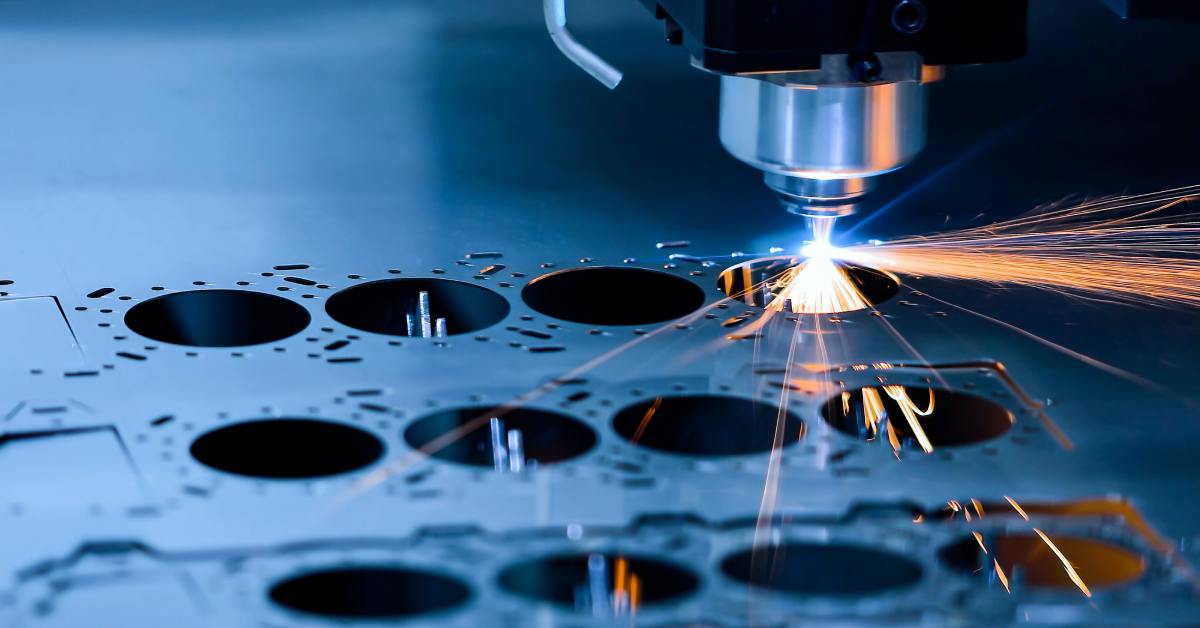

Thin-gauge metals are lightweight, flexible materials essential in a wide range of industries, from electronics and automotive manufacturing to aerospace engineering. These metals, typically less than 3mm thick, are used to create everything from intricate circuit boards to lightweight vehicle components. Working with such delicate materials requires a fabrication method that offers unparalleled precision and efficiency, ensuring the final product meets exact specifications without damage.

Laser cutting has become a cornerstone of thin-gauge metal fabrication for this very reason. To better understand why this is, we’re here to dive into the role of laser cutting in thin-gauge metal fabrication. That way, you can find a service that can provide you with exactly what you need.

Why Laser Cutting is Ideal for Thin-Gauge Metals

Laser cutting technology offers distinct advantages when working with thin-gauge materials. The process uses a high-powered, focused beam of light to melt, burn, or vaporize the material, resulting in exceptionally clean cuts and smooth edges. This non-contact method eliminates mechanical stress, which is crucial for preventing the warping and distortion common with thinner metals.

The precision of a laser also allows for the creation of incredibly intricate designs and complex geometries that would be difficult or impossible to achieve with other methods. Furthermore, the narrow kerf width—the width of the material removed during cutting—minimizes material waste, making the process both cost-effective and efficient.

Advantages Over Traditional Cutting Methods

Compared to traditional mechanical cutting methods like shearing or punching, laser cutting offers significant benefits. Mechanical processes exert physical force on the material, increasing the risk of burrs, rough edges, and structural damage, especially on thin sheets. Laser cutting avoids these issues entirely, delivering a superior finish that often requires no secondary processing.

The speed and automation capabilities of laser cutting also lead to faster production times. This makes it a highly scalable solution, suitable for both rapid prototyping and large-scale manufacturing runs. You can move from design to finished part quickly, accelerating your entire production workflow.

Applications in Thin-Gauge Metal Fabrication

The capabilities of laser cutting for thin-gauge metal fabrication have made it indispensable across numerous sectors. In the medical field, producers use it to craft precise components for surgical instruments and implantable devices. The decorative and architectural industries rely on it to create elaborate metal panels and signage. In microelectronics, laser cutting is essential for manufacturing small, complex parts for consumer gadgets and computing hardware.

The ability to produce custom parts and prototypes quickly also makes laser cutting a go-to choice for innovation and product development. If you’re looking for this level of precision when it comes to steel and metal sales near you, Thin Metal Sales is here to help. Learn more about why companies come to us when they need quality thin metal sheets.