How Automation Improves Metal Processing Accuracy

In the metal fabrication industry, margins for error are virtually nonexistent. Clients demand tight tolerances and fast turnaround times, pressuring manufacturers to deliver flawless components every single time. While manual craftsmanship holds value, it often struggles to meet the rigorous consistency required by modern engineering standards. This is where industrial automation steps in to bridge the gap.

By integrating advanced robotics and software into the production line, these companies elevate the quality of their output significantly. If you’d like to know more about how automation has improved metal processing accuracy, you’ve come to the right place.

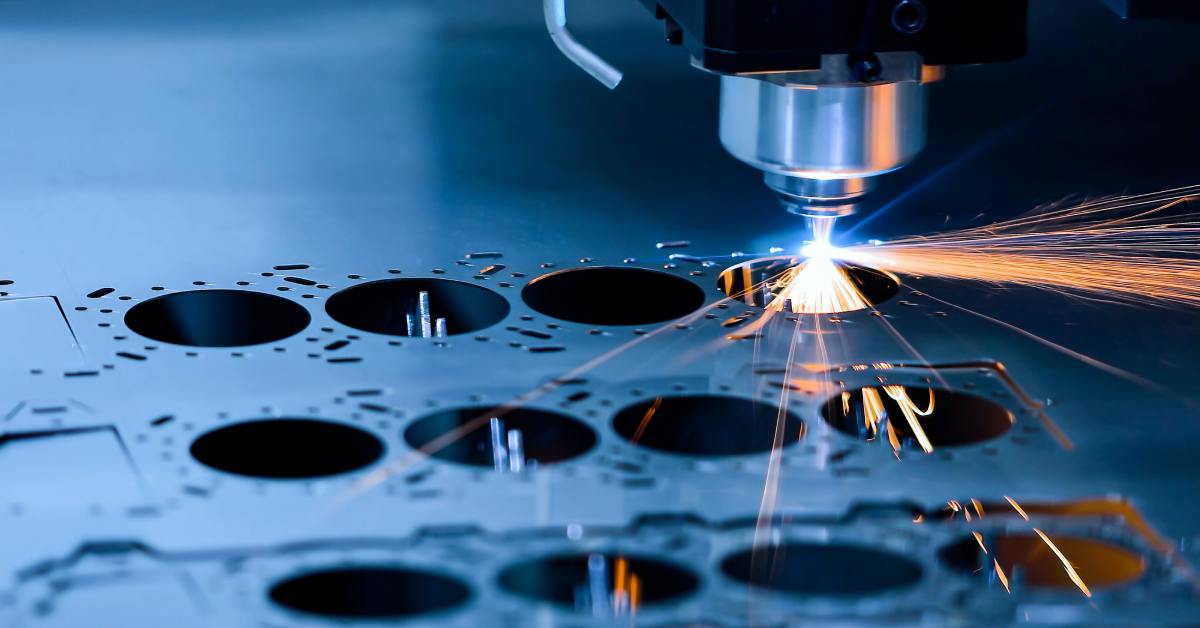

Precision in Cutting and Shaping

Achieving geometric complexity requires tools that go beyond the capabilities of the human hand. Automated equipment, particularly CNC machines, executes pre-programmed designs with micrometer-level precision. Whether using laser, plasma, or waterjet cutters, these systems follow digital schematics without deviation.

This eliminates the slight variances often introduced by manual operation. Consequently, companies also significantly reduce material waste generated by scrap parts. When teams rely on automated cutting, they ensure that the first part produced in a run is identical to the last, maintaining strict adherence to the original CAD model.

Real-Time Monitoring and Adjustments

Modern metal processing thrives on data. Intelligent fabrication systems now incorporate sophisticated sensors and AI-driven monitoring tools that track variables such as temperature, pressure, and tool speed in real-time.

These closed-loop feedback systems do not just record data; they act on it. If a sensor detects a drill bit heating up or a slight vibration in a lathe, the system instantly adjusts operational parameters to compensate. This dynamic response prevents thermal distortion and ensures that tooling wear doesn’t compromise the dimensional integrity of the final product.

Consistency in Repetitive Tasks

Variability is the enemy of mass production. Even the most skilled operators experience fatigue, which inevitably leads to minor inconsistencies over long shifts. Automation excels in this arena by performing repetitive tasks with unwavering uniformity.

Robotic arms and automated press brakes apply the exact same force and angle for every operation. This standardization ensures batch uniformity, which is critical for assembly lines where parts must fit together perfectly without manual modification. By removing the human variable from repetitive actions, companies can stabilize their throughput and guarantee a predictable, high-quality output.

Advanced Quality Control

Accuracy extends beyond fabrication; it encompasses verification. Automated inspection systems represent the final firewall against defective products reaching customers. High-resolution cameras and laser scanners examine surface finishes and dimensional accuracy at speeds impossible for human inspectors.

These automated optical inspection (AOI) units identify microscopic defects, such as hairline cracks or porosity, that the naked eye might miss. By catching these imperfections early, teams can prevent costly recalls, which will help their company maintain a reputation for superior quality.

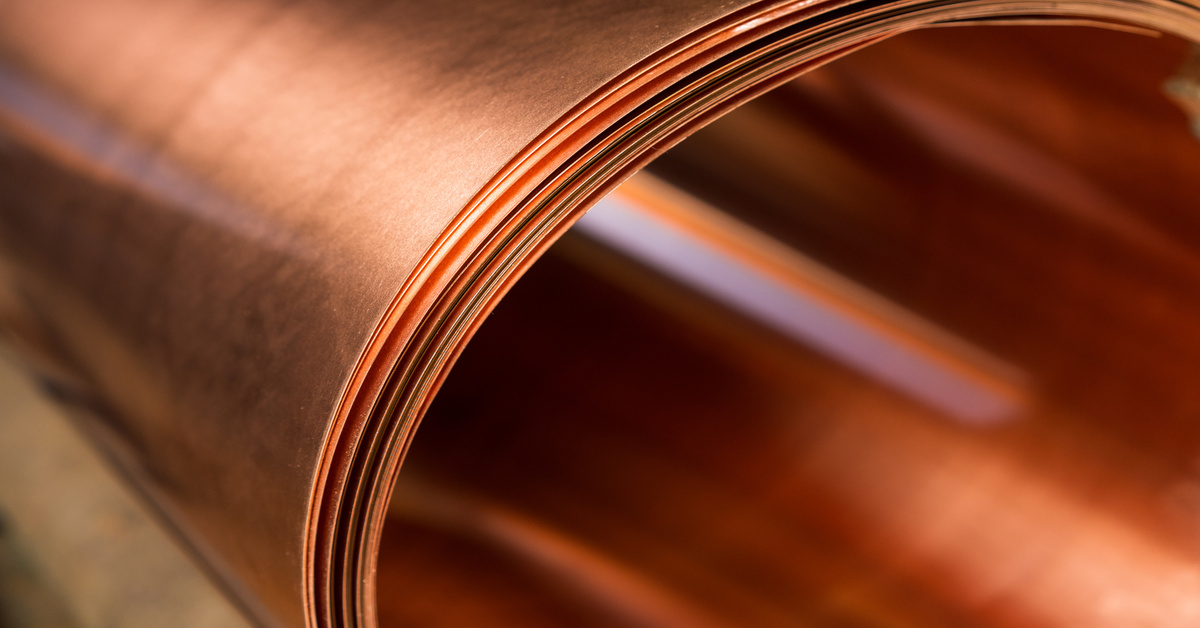

Where Thin Metal Sales Comes Into Play

If you’re looking for a company that utilizes these concepts to achieve a quality product, then you’ve come to the right place. Our business provides top-of-the-line copper sheet metal fabrication products by leveraging automation to the fullest. See how automation has improved our metal processing accuracy.