Ferritic vs. Austenitic Stainless Steel: Which Is Better?

Leave a Comment

Many industries routinely use stainless steel, including automotive, rocketry, construction, and aerospace. If you manufacture parts for one of these industries, you likely know a lot about the different types of stainless steel.

Today, we will discuss ferritic vs. austenitic stainless steel and determine which is better for industrial applications. Understanding the differences between the two is crucial when selecting the right material for a project.

A Brief Explanation of Ferritic Stainless Steel

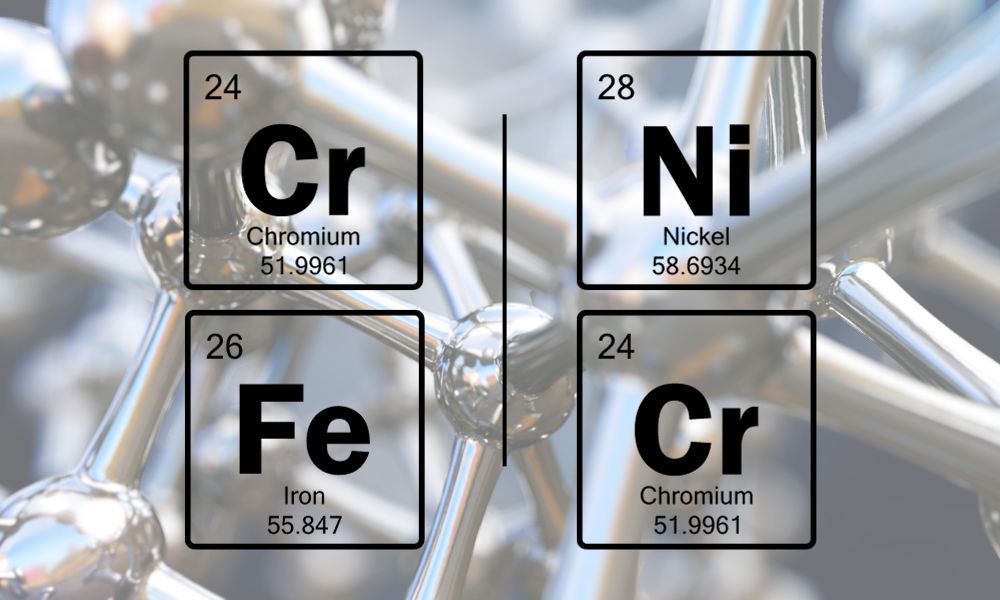

Ferritic stainless steel has a unique microstructure, primarily composed of iron and chromium. Thanks to this combination, ferritic stainless steel boasts good corrosion resistance, especially against hot water and atmospheric conditions. Often, you will find this type of steel in automotive parts, kitchen appliances, and even some architectural applications.

A Brief Explanation of Austenitic Stainless Steel

Rich in chromium and nickel, austenitic stainless steel is renowned for its exceptional resistance to corrosion and excellent formability. A key characteristic is its nonmagnetic nature when in its solution-annealed state. This nonmagnetic nature makes austenitic stainless steel a popular choice for kitchen equipment, industrial equipment, and chemical processing.

Comparing Ferritic and Austenitic Stainless Steel

Several distinctions stand out when comparing ferritic vs. austenitic stainless steel and determining which is better. First, austenitic stainless steel tends to be more corrosion-resistant than its ferritic counterpart. This resistance to corrosion makes it ideal for environments that are more aggressive or require rigorous sanitation, such as food processing.

Formability is another factor when comparing the two options. With its unique molecular structure, Austenitic stainless steel is easier to weld and form than ferritic stainless steel. This flexibility explains why an experienced stainless steel sheet supplier might recommend austenitic steel for intricate designs or welding-heavy projects.

Additionally, ferritic stainless steel is generally less expensive than austenitic steel. Plus, its magnetic nature can provide several benefits in certain applications. It also has better resistance to stress corrosion cracking than its austenitic counterpart.

So Which Is Better?

When comparing each type of stainless steel, it is not about crowning a winner but understanding which option best fits your needs. If you want something cost effective and durable for less aggressive environments, you might choose ferritic stainless steel. On the other hand, if corrosion resistance and formability top your list, then austenitic stainless steel is the way to go.

In any case, always consult with a knowledgeable stainless steel sheet supplier. At Thin Metal Sales, our team can provide invaluable insights into which steel best suits your project’s unique requirements. Contact us today for more information about our high-quality assortment of stainless steel materials.

A Quick Guide To Understanding How Alloys Are Made

Leave a Comment

Most people have heard the term alloy at least once in their lives. However, very few have researched the fascinating science behind alloy formation. Here is a quick guide to understanding how alloys are made.

What Is an Alloy?

An alloy is a combination of two or more metals or a metal and another element. Alloys are usually created to enhance certain properties like strength or resistance to corrosion. Think of it as a metallic superhero team-up, where each member contributes a unique skill to create an end product that is more formidable than its individual parts.

What Are the Most Common Alloy Materials?

While many alloy combinations are available, certain combinations have become more popular due to their enhanced properties. The most common alloy materials include:

- Brass: A blend of copper and zinc

- Bronze: Primarily made of copper, often combined with tin

- Stainless steel: Comprises iron, carbon, and at least 10.5 percent chromium

- Aluminum alloys: These alloys contain aluminum and other elements, like copper, manganese, silicon, or zinc

Many businesses worldwide use alloys to support their operations. For instance, a sheet metal supplier might have brass or stainless-steel alloys as part of their primary inventory so that it can cater to different manufacturing needs.

How Are Alloys Made?

Creating an alloy is not just about throwing metals into a pot and hoping for the best. There are specific methods involved in the process, each offering a unique way to create a final product with distinct properties.

Melting and Mixing Compounds

Melting and mixing compounds is the most traditional method to craft alloys. Manufacturers heat metals until they reach their melting point and mix them in predetermined proportions. Once thoroughly combined, the mixture is cooled down to form a solid alloy. Think of it as making a soup, in with manufacturers combining different ingredients to make a delicious concoction!

Powder Metallurgy

This technique skips the melting process altogether. Manufacturers grind metals into powders, mix them in the desired proportions, and compress them under high pressure. The resulting compact is then heated in a controlled environment, allowing the metals to bond. Manufacturers typically use this method when metals have vastly different melting points.

Ion Implantation

Ion implantation is an advanced method that involves firing ions (charged atoms) of one metal into the surface of another at high velocities. This process changes the structure of the surface, creating a thin layer of alloy. It is like giving the metal a facelift, enhancing its surface properties without affecting its core.

Alloys are complex constructions that have helped build our modern world. Next time you come across a metal object, be it a jewelry piece or a product from your trusted sheet metal supplier, take a moment to appreciate the science and artistry that went into creating it.

At Thin Metal Sales, our quick guide to understanding how alloys are made will remind you that combining different elements can sometimes lead to something incredibly powerful and beautiful! Contact us today for more information about our precision sheet metals for sale.