Ferritic vs. Austenitic Stainless Steel: Which Is Better?

Many industries routinely use stainless steel, including automotive, rocketry, construction, and aerospace. If you manufacture parts for one of these industries, you likely know a lot about the different types of stainless steel.

Today, we will discuss ferritic vs. austenitic stainless steel and determine which is better for industrial applications. Understanding the differences between the two is crucial when selecting the right material for a project.

A Brief Explanation of Ferritic Stainless Steel

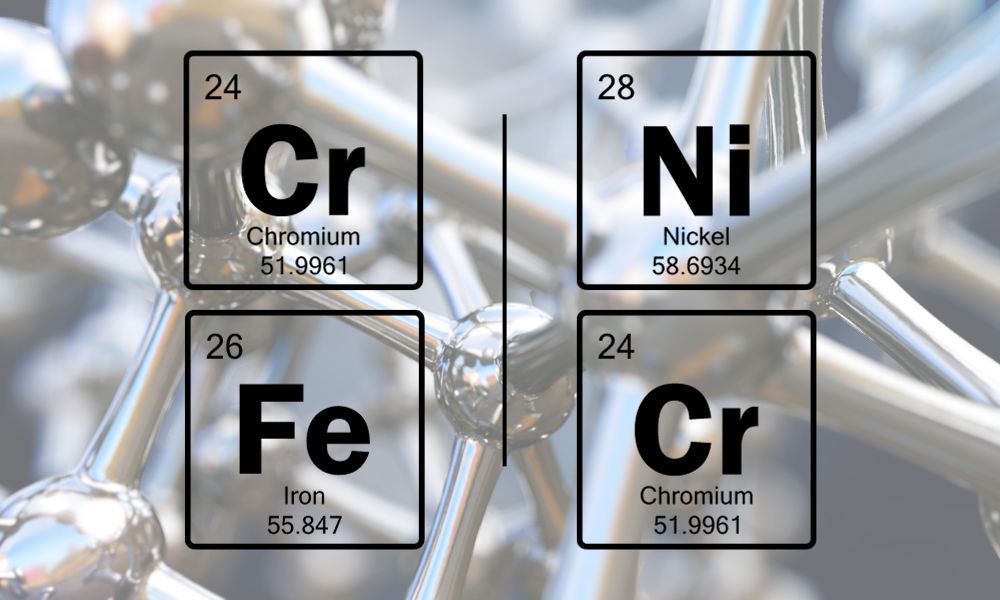

Ferritic stainless steel has a unique microstructure, primarily composed of iron and chromium. Thanks to this combination, ferritic stainless steel boasts good corrosion resistance, especially against hot water and atmospheric conditions. Often, you will find this type of steel in automotive parts, kitchen appliances, and even some architectural applications.

A Brief Explanation of Austenitic Stainless Steel

Rich in chromium and nickel, austenitic stainless steel is renowned for its exceptional resistance to corrosion and excellent formability. A key characteristic is its nonmagnetic nature when in its solution-annealed state. This nonmagnetic nature makes austenitic stainless steel a popular choice for kitchen equipment, industrial equipment, and chemical processing.

Comparing Ferritic and Austenitic Stainless Steel

Several distinctions stand out when comparing ferritic vs. austenitic stainless steel and determining which is better. First, austenitic stainless steel tends to be more corrosion-resistant than its ferritic counterpart. This resistance to corrosion makes it ideal for environments that are more aggressive or require rigorous sanitation, such as food processing.

Formability is another factor when comparing the two options. With its unique molecular structure, Austenitic stainless steel is easier to weld and form than ferritic stainless steel. This flexibility explains why an experienced stainless steel sheet supplier might recommend austenitic steel for intricate designs or welding-heavy projects.

Additionally, ferritic stainless steel is generally less expensive than austenitic steel. Plus, its magnetic nature can provide several benefits in certain applications. It also has better resistance to stress corrosion cracking than its austenitic counterpart.

So Which Is Better?

When comparing each type of stainless steel, it is not about crowning a winner but understanding which option best fits your needs. If you want something cost effective and durable for less aggressive environments, you might choose ferritic stainless steel. On the other hand, if corrosion resistance and formability top your list, then austenitic stainless steel is the way to go.

In any case, always consult with a knowledgeable stainless steel sheet supplier. At Thin Metal Sales, our team can provide invaluable insights into which steel best suits your project’s unique requirements. Contact us today for more information about our high-quality assortment of stainless steel materials.