The Inherent Characteristics of Copper vs. Brass Sheet Goods

Comments Off on The Inherent Characteristics of Copper vs. Brass Sheet Goods

When selecting metal sheet goods for a project, understanding their distinct characteristics is essential, especially when it comes to copper and brass. Both materials offer unique properties that make them well-suited to different applications. If you’d like to know more, here’s a quick look at the difference between the characteristics of copper and brass sheet goods.

Composition and Appearance

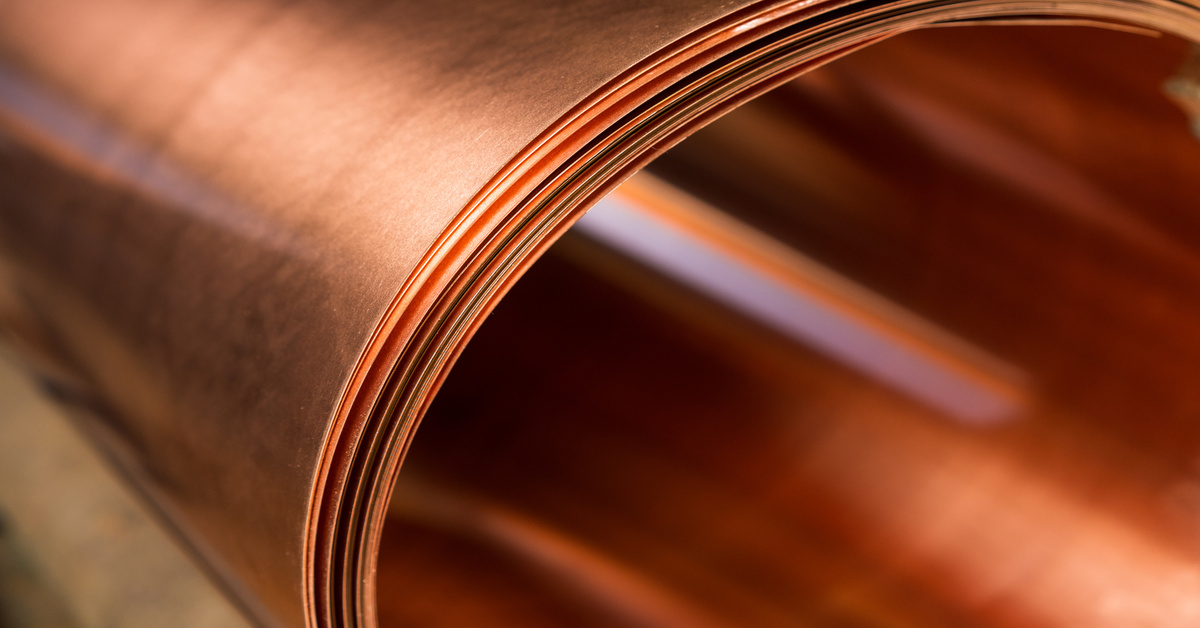

Copper is a pure elemental metal, prized for its distinctive reddish-orange color. Over time, exposure to the elements causes copper to develop a natural patina—a greenish layer that protects the underlying metal while adding visual character. This aging process makes copper particularly appealing for applications where aesthetic evolution is desired.

Brass, by contrast, is an alloy created by combining copper with zinc. The zinc content determines the final appearance, producing shades ranging from pale gold to deep bronze. You can specify the exact composition to achieve your desired color and performance characteristics. Unlike copper’s patina, brass tends to maintain its metallic luster longer, though it may develop tarnish depending on environmental conditions.

Durability and Strength

The mechanical properties of these materials differ significantly. Copper’s softness and malleability make it exceptionally workable. You’ll find it responds well to forming, bending, and detailed fabrication work. This flexibility proves invaluable when your project requires intricate designs or tight radius turns.

Brass delivers greater hardness and wear resistance due to its alloyed composition. The zinc content increases the material’s strength while maintaining reasonable workability. This enhanced durability makes brass sheet goods ideal for applications that demand both aesthetic appeal and structural integrity.

Corrosion Resistance

Both materials excel in corrosive environments, though they perform differently. Copper develops its protective patina layer naturally, providing excellent long-term resistance to moisture, salt spray, and atmospheric conditions. This self-protecting characteristic makes copper a reliable choice for exterior applications and marine environments.

Brass also resists corrosion effectively, particularly in applications involving water and mild chemicals. However, it may show visible tarnishing more readily than copper, especially in industrial atmospheres containing sulfur compounds. You can mitigate this through proper surface treatments and regular maintenance protocols.

Common Applications

Copper sheet goods find extensive use in roofing systems, where their weather resistance and aesthetic qualities combine to create durable, attractive installations. The material’s excellent electrical conductivity makes it indispensable for electrical wiring and bus bar applications. Artisans and metalworkers also favor copper for sculpture and decorative metalwork.

Brass serves different industrial needs. Its acoustic properties make it the standard material for musical instrument manufacturing. Plumbing fixtures benefit from brass’s antimicrobial properties and corrosion resistance. Architectural designers specify brass sheet goods for decorative panels, nameplates, and trim work where its golden appearance complements other building materials.

Where To Get Your Copper and Brass Sheets

Now that you’re familiar with the inherent characteristics of both copper and brass sheet goods, it’s time to make a decision on which best fits your project’s needs. Fortunately, no matter which type you choose, Thin Metal Sales is here to help. We’re a proud brass and copper sheet supplier and can provide you with as many sheets as you need.

Types of Alloys Used in Aluminum Sheet Composition

Comments Off on Types of Alloys Used in Aluminum Sheet Composition

Aluminum sheets are essential for countless industries, from construction and automotive to aerospace and packaging. While pure aluminum offers lightweight properties and natural corrosion resistance, alloying transforms this versatile metal into a high-performance material tailored to specific applications.

By adding various elements to aluminum, manufacturers enhance its strength, durability, and overall versatility. Before purchasing any yourself, take the time to understand the most commonly used alloy compositions. This will help you select the right aluminum sheet for your project’s unique demands.

Aluminum-Manganese Alloys

Aluminum-Manganese alloys used in the 3xxx series stand out for their excellent corrosion resistance combined with moderate strength. Manganese, as the primary alloying element, gives these sheets reliable performance in environments where rust and degradation pose concerns. You’ll find 3xxx alloys widely used in roofing and siding applications, where weather resistance is paramount.

The beverage can industry also relies heavily on this series—its formability and corrosion resistance make it ideal for containing liquids while maintaining structural integrity. If your project requires a balance between workability and environmental durability without extreme strength requirements, 3xxx aluminum alloys used in sheet composition deliver consistent results.

Aluminum-Magnesium Alloys

When your application demands both high strength and superior corrosion resistance, the 5xxx series of aluminum-magnesium alloys rises to the challenge. Magnesium content significantly boosts these alloys’ mechanical properties while maintaining excellent resistance to saltwater and harsh conditions.

Marine environments particularly benefit from 5xxx aluminum sheets—boats, ship components, and offshore structures utilize this series extensively. The automotive industry has also embraced these alloys for body panels and structural components where weight reduction and strength are equally critical. You can count on 5xxx series sheets when working in corrosive settings that require robust performance.

Aluminum-Magnesium-Silicon Alloys

The Aluminum-Magnesium-Silicon alloys used in the 6xxx series by aluminum sheet manufacturers provide a well-balanced combination of strength, corrosion resistance, and machinability, making them incredibly versatile. The addition of both magnesium and silicon creates alloys that are heat-treatable, allowing you to further enhance their properties through thermal processing.

This series dominates structural applications—architectural extrusions, bridge components, and transportation infrastructure frequently specify 6xxx alloys. Their excellent weldability and finishing characteristics make them particularly attractive when you need both functional performance and aesthetic appeal. If you’re working on projects that require precise fabrication with reliable structural integrity, 6xxx series aluminum sheets offer the flexibility you need.

Aluminum-Zinc Alloys

For applications demanding maximum strength, the 7xxx series represents the pinnacle of aluminum alloy performance. Zinc, as the primary alloying element, often combined with magnesium and copper, creates extremely high-strength materials that rival some steels.

The aerospace industry depends on 7xxx alloys for aircraft frames, wing structures, and other critical components where the strength-to-weight ratio is non-negotiable. Defense applications similarly rely on this series for military equipment and vehicles. While 7xxx alloys may sacrifice some corrosion resistance compared to other series, their exceptional mechanical properties make them indispensable for engineering under extreme loads and demanding conditions.