How Stainless Steel Sheets Are Used in the Food Industry

Leave a Comment

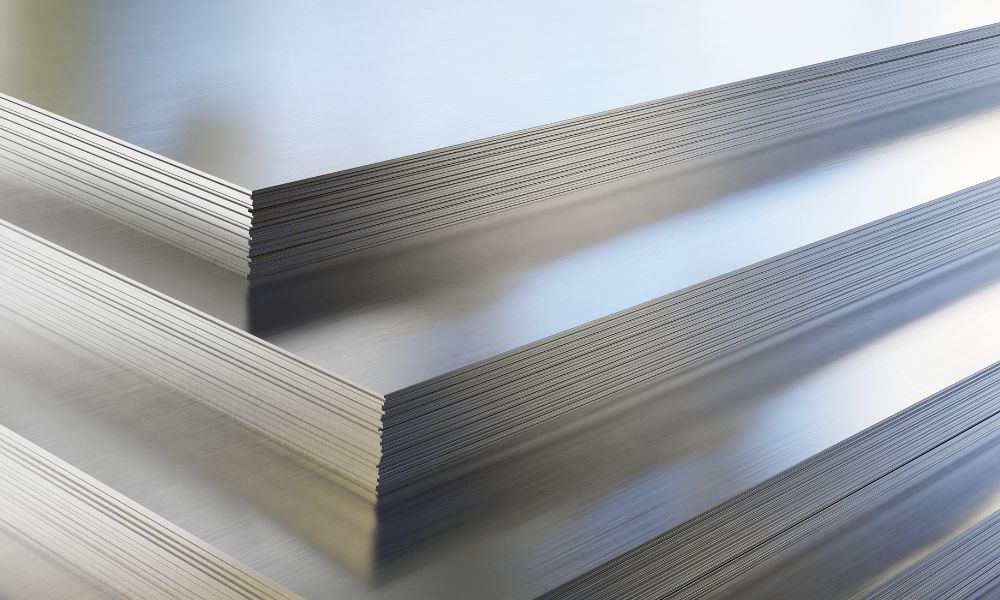

The food industry, a behemoth of tastes, textures, and health regulations, has found an unwavering ally in the gleaming panels of stainless steel. This alliance isn’t just about sparkle; it’s a testament to the durability and strength that stainless steel provides for the entire industry. Find out how stainless steel sheets are used in the food industry below.

Hygienic Surfaces That Meet the Highest Sanitation Standards

When it comes to food preparation and production, cleanliness is the golden rule. Stainless steel sheets shine brightest here, offering surfaces that bacteria dread. Their nonporous nature means that spills, splatters, and smears have nowhere to hide.

Whether it’s the chopping block at a bustling restaurant or the expansive counters of a food processing plant, stainless steel protects against germs and contaminants. It helps cleanliness reign supreme.

Creating Durable Processing Equipment and Machinery

Stainless steel sheets are the material of choice for food processing equipment and machinery. From mixers to grinders, these metallic marvels resist wear and tear and withstand the rigorous demands of daily use.

Unlike other materials that might crack under pressure or corrode during chemical reactions, stainless steel holds its ground. Thanks to this durable metal alloy, your machinery will keep running smoothly and efficiently.

Manufacturing Corrosion-Resistant Storage Solutions

When storing perishables or potent ingredients, the food industry turns to stainless steel for solutions that withstand time and temperature. Stainless steel sheets can become corrosion-resistant containers and vats, creating an impervious fortress against the elements.

These storage solutions keep food safe, preserve the purity of flavors, and protect against contamination, maintaining food quality from storage to serving.

Helping With Food-Grade Transportation and Packaging

The journey from farm to table is full of potential pitfalls. Thankfully, stainless steel sheets keep everything running smoothly, specifically in the transportation and packaging sectors.

Containers and storage units that use this material protect food against environmental hazards and contamination during transit. This protection is especially important since freshness and hygiene are nonnegotiable for food products.

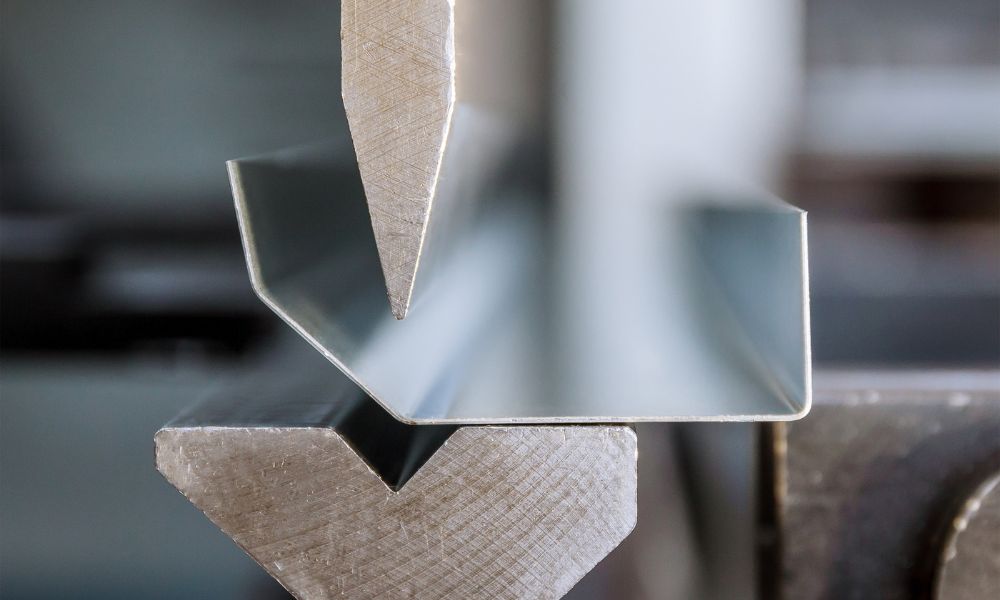

Creating Intricate Equipment and Unique Design Solutions

Stainless steel sheets provide a playground for innovation and intricate design in the food industry.

Customized equipment tailored to specific culinary tasks, artistic installations in dining establishments, and ergonomic designs that enhance efficiency are all possible thanks to the versatility and workability of stainless steel.

This material doesn’t just solve problems; it inspires solutions that are as elegant as they are effective.

Stainless steel sheets help shape the narrative of strength, sanitation, and innovation within the food industry. As the industry continues to evolve, stainless steel’s role only grows, highlighting the importance of finding stainless steel sales from trusted suppliers like Thin Metal Sales.

Our stainless steel sheets are used in the food industry to maintain the integrity and efficiency of food production and presentation. Contact us today to learn how our quality products have become the unsung heroes of food businesses nationwide.