Care, Maintenance, and Long-Term Storage of Copper and Brass

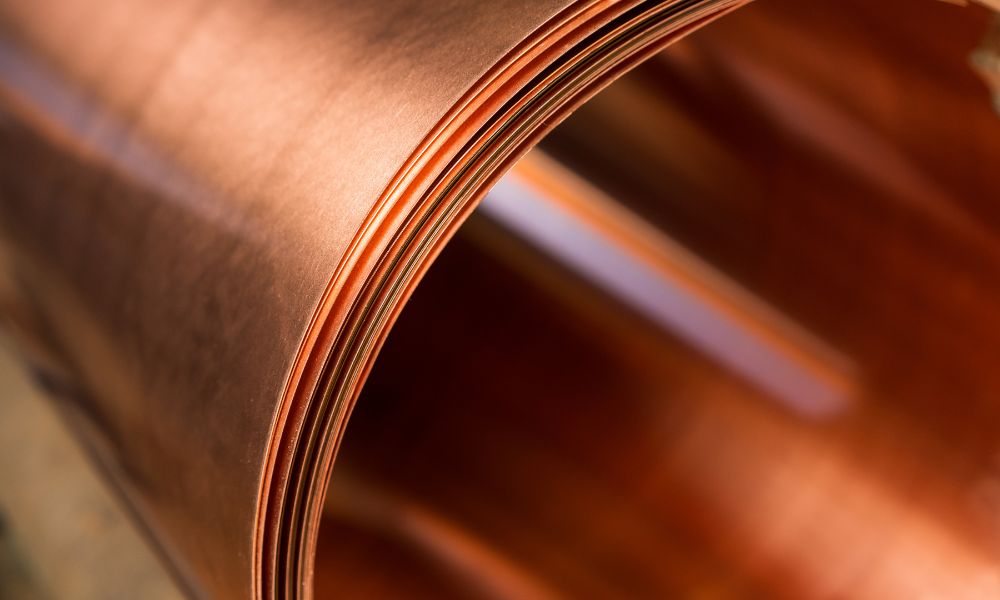

Aerospace manufacturers rely on copper and brass for their strength, conductivity, and workability. However, even the toughest alloys deserve more than a quick wipe-down before you place them on the shelf. When you care for and store these metals correctly, they resist corrosion and warping.

You can keep components ready for production instead of turning them into expensive scrap. In this guide, we’ll share tips on the care, maintenance, and long-term storage of copper and brass.

Daily Handling and Routine Care

Copper and brass look tough but demand regular attention. Oils from your hands leave fingerprints that etch over time, so wear clean gloves every time you touch sheets or parts.

Dust and debris can scratch surfaces, so wipe them with a lint-free cloth before and after you handle them. Use a mild soap solution for tough spots, and avoid harsh products that strip protective layers. These small actions extend each piece’s usable life and prevent defects down the line.

Maintenance That Pays Off

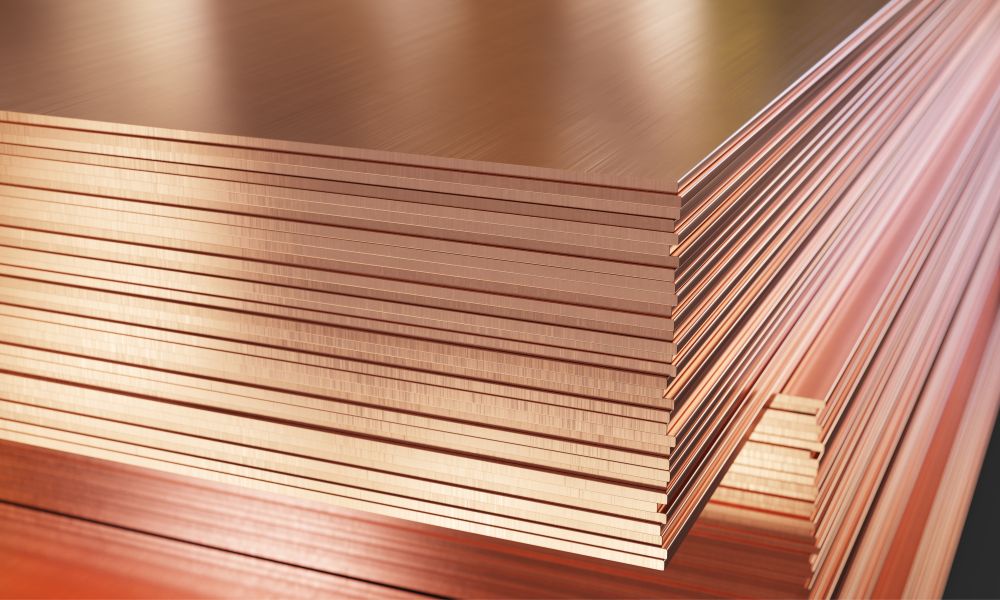

Regular upkeep cuts waste and saves money, and every aerospace operation values that. Inspect your metals to catch discoloration or early rust before it spreads. If you spot trouble, polish the area with a non-abrasive cleaner designed for non-ferrous metals.

A brass and copper sheet manufacturer will confirm that you can keep downtime low and maintain usable stock by routinely polishing and applying protective coats. Consistent care beats scrambling for replacement parts. The reward is cleaner, more reliable materials that are ready for high-performance applications.

Smart Storage for Long-Term Use

Storage mistakes can wipe out all the effort you put into cleaning and polishing. Keep copper and brass away from moisture, extreme heat, and direct sunlight. A controlled environment stops metals from oxidizing and prevents them from warping.

Stand sheets upright on padded racks to prevent scratching, and store smaller parts in sealed, labeled containers lined with anti-tarnish paper. Keep different metals in separate bins so they don’t react and corrode. When you store these materials wisely, you protect your investment and keep components ready for use.

Protecting the Future of Your Materials

Caring for copper and brass requires attention to detail, but the rewards show up in every finished part. By handling metals correctly, sticking to a maintenance schedule, and storing them in controlled conditions, you can avoid setbacks.

Your operation benefits from reliable stock that maintains its quality from the day it arrives until the moment it enters production. With this approach, you secure long-term performance and reduce waste. That’s why prioritizing the care, maintenance, and long-term storage of copper and brass is a decision you’ll never regret.