Why Stainless Steel Is Corrosion Resistant

Manufacturing any machine or structure requires a careful selection of work materials. Whether you’re working with aluminum, steel, or beyond, you need to know how the metal will react in your application. For instance, stainless steel has a reputation for corrosion resistance, making it a helpful material in various projects.

Making the most out of stainless steel’s corrosion defenses requires an understanding of how it achieves those defenses. Discover why stainless steel is corrosion-resistant today so you can learn how to utilize it at work.

What Is Stainless Steel?

Explaining corrosion resistance requires looking at what stainless steel even is. Steel already has its useful applications, so why rely on stainless steel in some situations? One additional component to the design opens many doors for manufacturers. It all comes down to the alloys, primarily Chromium content. Stainless steel is a steel alloy that contains at least ten percent Chromium.

Corrosion Resistance

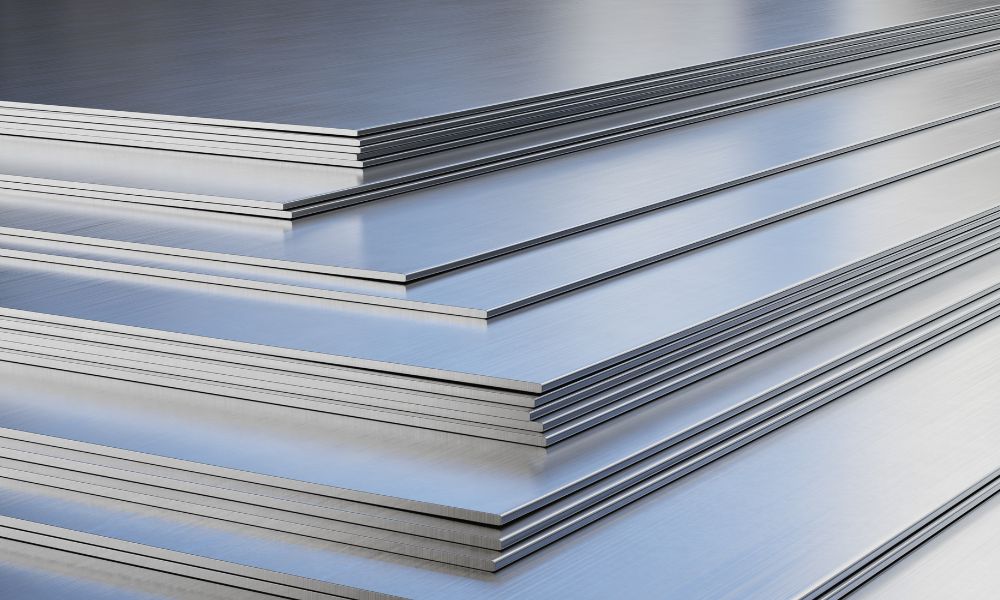

Thin Metal Sales is a stainless steel sheet supplier, so it’s important for us to understand what makes this material so adept at combating corrosion. Chromium is a special ingredient in stainless steel that improves corrosion resistance. As useful as it may be, steel on its own can rust quite easily.

Chromium reacts with the air around the stainless steel to create a thin protective layer on the surface. Thanks to that protective layer, stainless steel can combat corrosion. Now, it’s time to take a closer look at the importance of the reactive surface.

Useful Applications

Understanding why stainless steel is corrosion-resistant also requires looking at the common applications. For instance, the aerospace industry continues to use stainless steel for its applications. Vehicles, such as aircrafts, must have ample protection from the elements in flight, and stainless steel assists with that superbly.

Structures in marine applications also utilize stainless steel to prevent the saltwater from corroding it quickly. If you need ample corrosion resistance in your structure, consider using stainless steel to bring the project together.