Tips for Cutting and Shaping Copper Sheet Metal

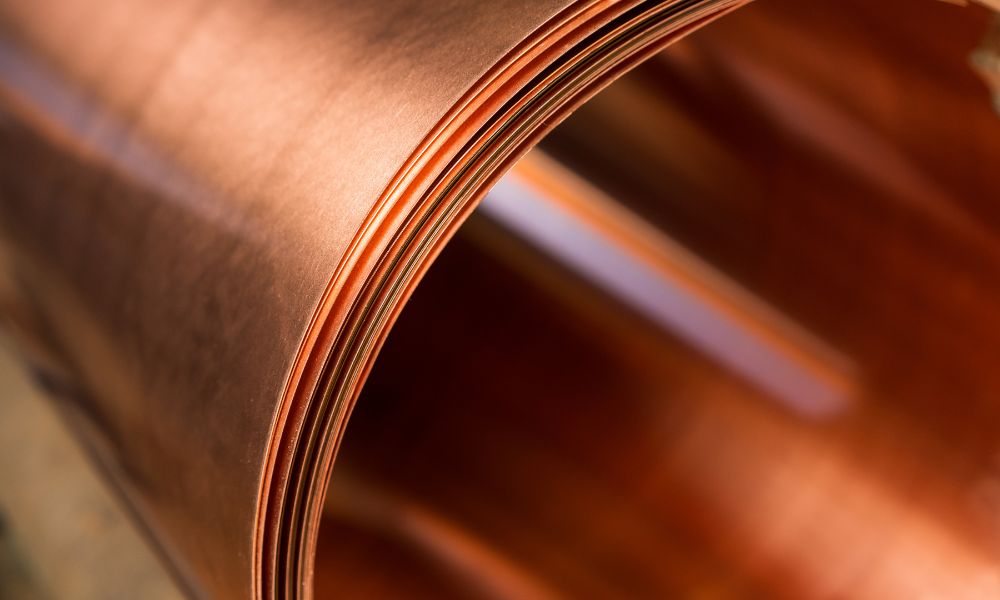

Copper sheet metal is a versatile material that plays a critical role in various industrial applications. Whether you’re crafting intricate electrical components or fabricating large-scale architectural features, mastering the art of cutting and shaping copper sheet metal is essential.

With the right techniques and tools, working with copper can be efficient and enjoyable. This guide covers the best practices to help you handle copper sheet metal like a pro.

Choosing the Right Tools for the Job

Selecting the right tools ensures precision and minimizes material waste. For thinner copper sheets, hand tools like metal shears or aviation snips work well, allowing for clean, controlled cuts.

If working with thicker gauges, consider power tools such as nibblers or plasma cutters to speed up the process. When precision is key, a jeweler’s saw or a CNC machine can offer detailed results.

Always use a sturdy work surface and secure the copper sheet properly before cutting to prevent unnecessary movement. A sharp blade and steady hand make all the difference.

Best Techniques for Cutting Copper

Proper technique makes cutting copper sheet metal more efficient and less frustrating. When using snips, start with a controlled initial cut to guide the tool smoothly along the marked line.

A scoring knife is ideal for thinner sheets—simply score the line multiple times, then bend the sheet back and forth until it snaps cleanly. For power tools, keep your hands steady and move at a consistent speed to avoid jagged edges.

If burrs appear along the cut edge, a fine file or sandpaper quickly smooths them out. Precision and patience go a long way in achieving professional results.

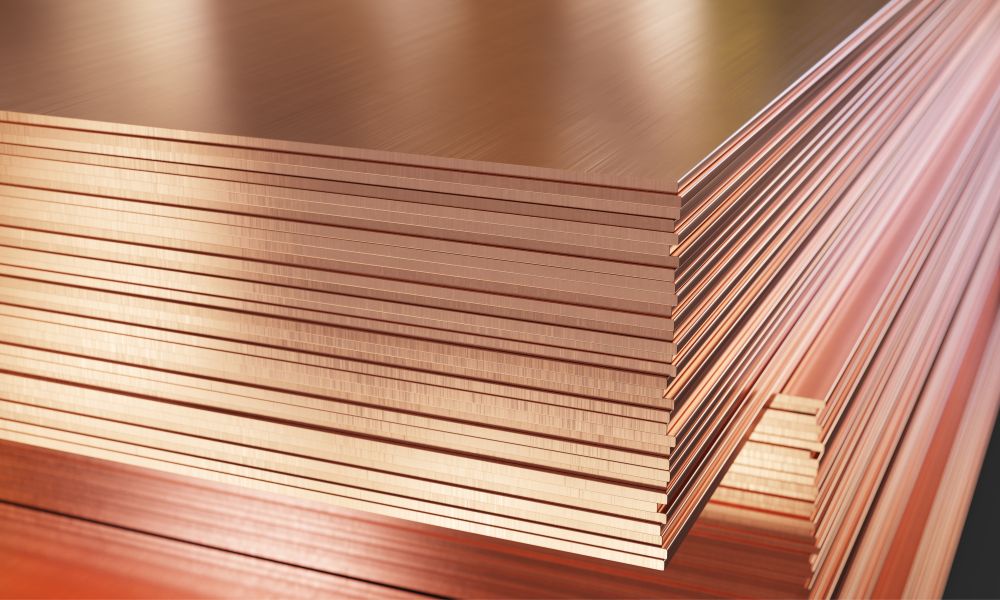

Shaping Copper for Industrial Use

Once cut, shaping copper sheet metal requires the right combination of force and finesse. A mallet and sandbag work well for gentle curves, while a metal brake creates sharp, clean bends.

When forming complex shapes, annealing the copper—heating it until it’s red-hot and then cooling it—softens the metal, making it more malleable. Clamps and wooden blocks help maintain the desired shape while working.

Always account for material thickness when bending to avoid cracks or uneven results. The right shaping techniques ensure durability and precision in your final product.

Final Touches and Safety Considerations

After cutting and shaping, refining the edges ensures a polished, professional finish. Deburring tools, files, or a simple sanding block can smooth out any rough spots.

If your project requires welding or soldering, clean the surface thoroughly to ensure strong adhesion. Safety is just as important as technique—always wear gloves and safety goggles to protect against sharp edges and flying debris.

With the proper approach, cutting and shaping copper sheet metal becomes a smooth, rewarding process. Whether you’re working with thick industrial plates or a thin copper sheet, these techniques help you achieve precision and efficiency. Visit Thin Metal Sales to find the perfect materials for your next project.