The Different Types of Sheet Metal Fabrication Techniques

The world of sheet metal fabrication isn’t as scary as it appears. In fact, without this process, society would have a difficult time meeting its basic needs. Workers use various techniques to shape and manipulate metal sheets into their desired form, from bending to welding. Let’s explore the different types of sheet metal fabrication techniques that turn metal into a treasure trove for creative and practical projects.

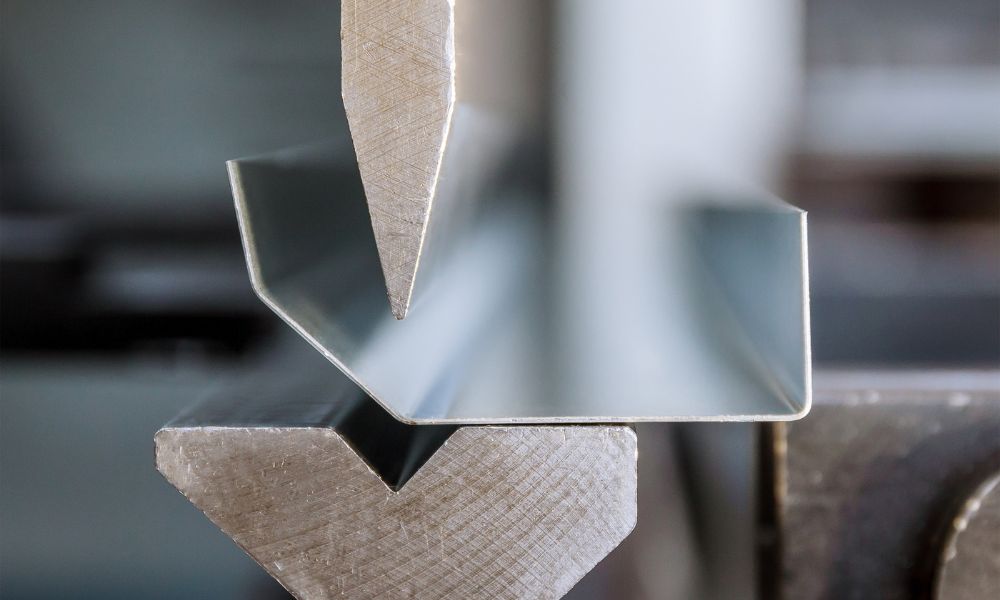

Bending

Bending is a fundamental technique in which workers bend sheet metal along a straight axis to form angles or curves. They accomplish this goal using specialized equipment like press brakes or rollers, which allows for precise manipulation of the metal’s shape.

Cutting

Metal cutting involves removing excess material from a metal sheet to achieve the desired size or shape. Workers commonly use techniques like laser cutting, plasma cutting, or water cutting to cut through metal of varying thicknesses precisely and efficiently.

Punching

Punching is a method for creating holes or other geometric shapes in a metal sheet. This process typically involves using a punch and die set, where the punch applies force to penetrate the metal sheet, leaving behind the desired shape.

Shearing

Shearing is the process of cutting straight lines on a metal sheet using shear blades. It often helps trim the edges of the sheet or separate the sheet into smaller pieces with clean, straight cuts.

Stamping

Stamping involves pressing a metal sheet against a die to form specific shapes or patterns. Workers use this technique to mass-produce intricate designs or add logos and labels to metal components.

Welding

Welding is the process of joining two or more metal pieces together using heat and pressure. It’s essential for fabricating large structures or assemblies from metal sheets, providing strength and stability to the final product.

The world of sheet metal fabrication is vast and diverse, offering multiple techniques to transform raw metal sheets into functional components and artistic creations. Whether bending, cutting, punching, shearing, stamping, or welding, each technique plays a crucial role in bringing ideas to life.

So the next time you’re searching for steel and metal sales near you, consider what’s possible with Thin Metal Sales. Our different sheet metal fabrication techniques will provide you with the perfect metal for your newest project.