Why Choose 7-17 Stainless Steel?

69% of all steel is recycled in North America every year. This ends up being almost more than 80 million tons of steel. It’s important to make sure you’re using the best steel for whatever you require it for. 17-7 stainless steel has many great qualities and can serve a variety of purposes. 17-7 stainless steel has two main qualities that make this steel an excellent choice. Those qualities are high corrosion resistance and high strength. This stainless steel is precipitation hardened, meaning it possesses not only high strength, but high hardness, great corrosion resistance, good fatigue properties, and minimal distortion with high heat temperatures.

Aerospace Applications

Because of these particular properties, 17-7 stainless steel is great for aerospace applications. This kind of stainless steel is preferred over another type of metal like aluminum. It’s the better choice for aerospace applications because of how it has high corrosion resistance, high strength, and high formability. Being able to withstand high heat temperatures without distorting is also very important for aerospace applications, making 17-7 stainless steel the perfect option.

Food Processing Equipment

17-7 Stainless steel can withstand high heat temperatures, making it great for food processing equipment. Like other steels, like 302 stainless or 304 stainless, 17-7 stainless steel does develop rust over time with heavy use. However, it rusts significantly less than other steels, making it the option to produce the least amount of rust. This makes it a safe option for food processing equipment.

Chemical Processing Equipment

Whenever processing any kind of chemical, it’s important to use a metal that can withstand any condition. Chemical processing equipment not only requires a metal that can withstand high heat temperatures, but it needs a metal with high corrosion resistance, fatigue properties, and high strength as well. 17-7 stainless steel contains all of these properties, so it’s no surprise that it’s a go-to option for chemical processing equipment.

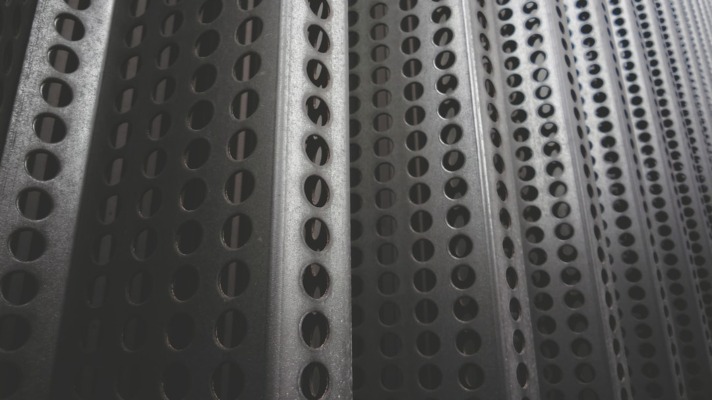

General Metalworking

While this particular stainless steel is great for harsher uses, it’s also great for minimal or general metalworking. Simple machinery that requires springs or washers is perfect for 17-7 stainless steel. Again a lot of general metalworking machines require metals that can withstand very high temperatures, and 17-7 stainless steel can do just that.

Oil and Petroleum Refining Equipment

Metal that works closely with oil and petroleum must have a high resistance on wearing down. Oil can make metal rust more and break them down, which can be costly if the wrong metal is chosen. 17-7 stainless steel is known for being a great option for oil and petroleum refining equipment. It has a high resistance on wearing down and does not rust as much as another metal would in that environment.

17-7 stainless steel is a great metal that has a variety of uses it is perfect for. It’s properties allow it to be a great option for both heavier metalwork and general metalwork. It’s a reliable type of metal that will last longer and continue to be durable in intense environments.